More, recently Kyle switched gears to work on the final look of the 6.0, decking it out with an all-inclusive pulley drive system by Eddie Motorsports. The complete pulley drive system comes with a lot of upgraded components and is the ideal conversion for any Chevrolet V8 engine. The system will eliminate the original v-pulley system and bolt on the S-Drive for the modern serpentine drive system Kyle desires for the Chevelle.

Pulley Drive System Installation

Available in a variety of finishes, each S-Drive system features CNC-machined aluminum brackets, pulleys, and covers along with the components listed below.

- Powermaster 105 amp alternator (140 amp for LS models)

- Edelbrock water pump Sanden SD-7 compressor (where applicable)

- Maval power steering pump

- Gates serpentine belt

- Gates tensioner ATI damper (LS models)

Check out the engine transformation in the episode below.

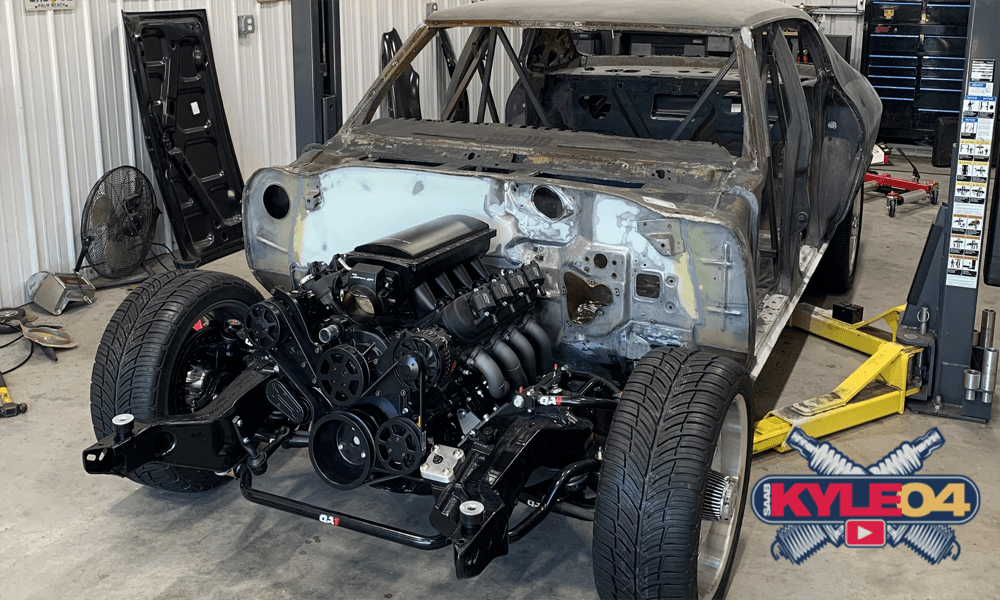

Mounting Body to Frame

Once the bedliner has sufficient time to cure, Kyle and Joe will roll it over to fabrication and set it on the frame. To fully prepare for mounting, Joe painted the firewall a satin black to match to frame. Because the Firewall that Original Parts Group supplies are for coupe models, a little finessing was necessary to make it compatible with the sedan.

Firewall w/ A/CPart# CH27196

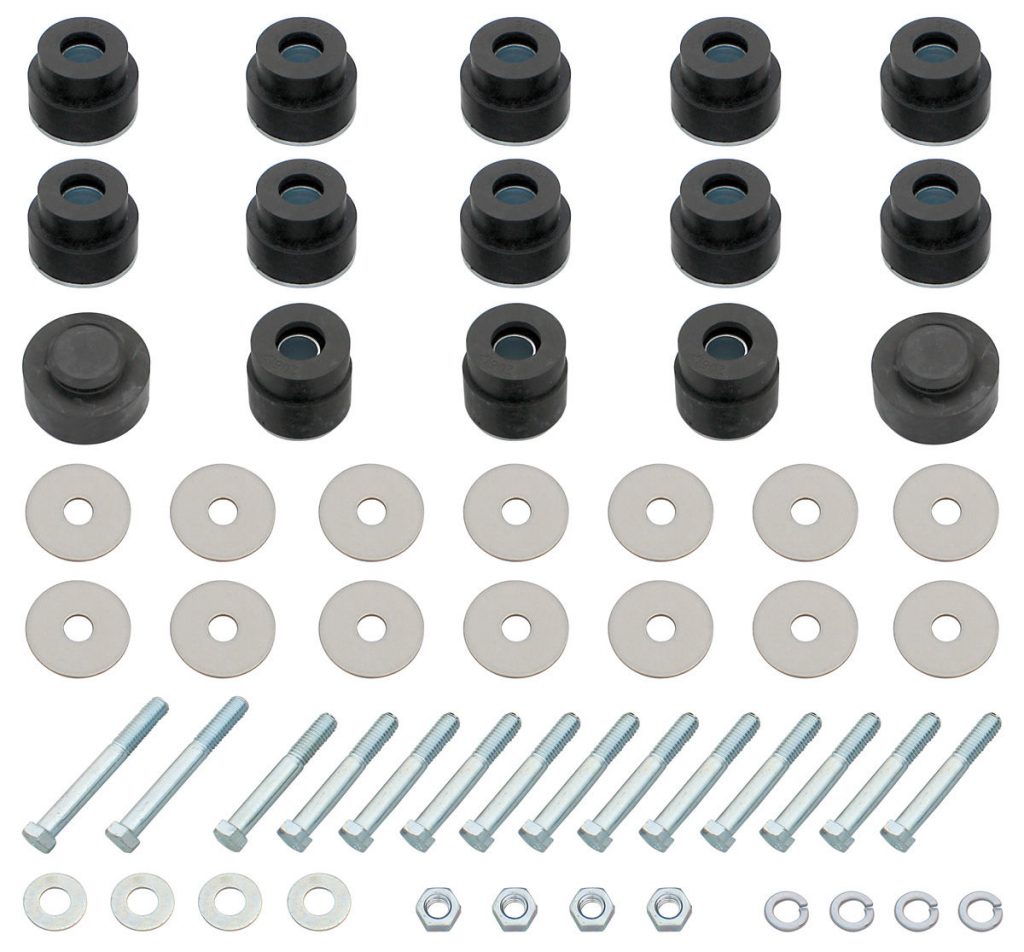

While Joe took to painting the firewall, Kyle began installing a body bushing kit by RESTOPARTS. While the fitment of the kit was good, the bushings are intended for a coupe and required some re-alignment.

RESTOPARTS bushings are produced in custom, case-hardened steel tools that provide a consistent, precise, rubber bushing every single time. In addition to OPGI’s finely reproduced rubber bushings, it’s also noteworthy that each steel insert is stamped the right way in authentic zinc and the included installation hardware is zinc coated for long-lasting corrosion resistance.

Check out those installations and the monumental progress made by Kyle and Joe bringing the body and frame together in the video below. Next up, Kyle and Joe will address the rust issues in the cowl area, rear window, and other small patches. Stay tuned!

Leave a Reply